Langfang Quanzhen Auto Parts Co., Ltd. supports the customization of various auto parts!

-

Quan Zhen Auto Parts

The company supplies parts to domestic and international automakers such as FAW Group, Changan Group, JAC Group, BAIC Group, and BAIC Foton.

了解更多scroll downHot Products

Our company has strong technical strength and perfect testing methods. It is equipped with direct-reading spectrometers, two-dimensional imaging detection, pneumatic gauges and other testing equipment, and adopts a scientific management model. From product design, material selection, process flow, production management, and quality inspection, each link is strictly controlled to meet customers' high-standard quality requirements.

About Us

Langfang Quanzhen Automobile Parts Co., Ltd.

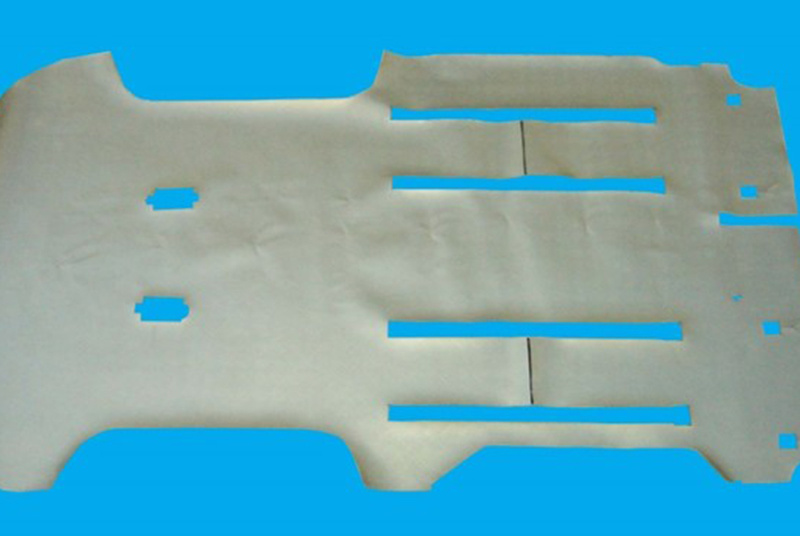

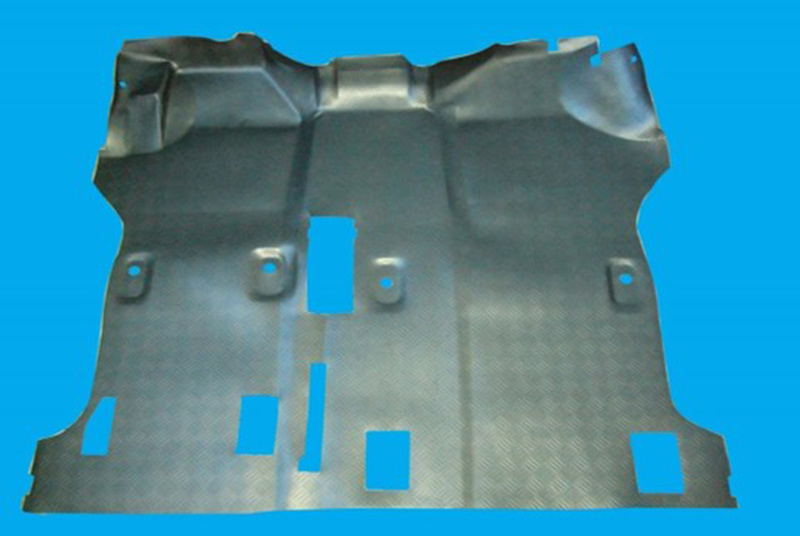

Langfang Quanzhen Automobile Parts Co., Ltd. is located in Dacheng County, Langfang City, Hebei Province, China, in the Bohai Rim economic zone, which is one of the most economically active areas in North China. It is 130 kilometers away from Beijing and 70 kilometers away from Tianjin. It enjoys a superior geographical location and convenient transportation. Founded in 1997, the company is a newly emerging private technology enterprise. The auto parts factory covers an area of 66,000 m2, the rotomolding factory covers an area of 80,000 m2, and the phase I factory building covers an area of 10,000 m2. There are more than 400 employees and nearly 100 million yuan in assets. In 2006, the company successively passed the ISO/TS16949 quality management system certification, ISO14001 environmental management system certification, OHSAS18001 occupational health management system, and safety production standardization certification. It is a national enterprise with integrity and law-abiding, a national Ministry of Commerce comprehensive credit rating AAA① level enterprise, and a provincial enterprise with integrity and trustworthiness. Our main products are sun visors, headliners, carpets, sound insulation and heat insulation products, SMC, heavy GMT products, and injection molding and rotomolding products. There are more than 60 technical personnel. The company has established an advanced technology development center and uses "three-coordinate laser measuring system", three-coordinate marking machine, CNC machining center and other development equipment for product development, and can use two-dimensional/three-dimensional software for forward and reverse development and design. The company owns imported "robot ultra-high pressure water jet cutting system" from American Fortune Company, introduced rotomolding equipment from the United States and Germany, domestic "automobile top cover interior/carpet automatic production line", and large injection molding machines, SMC large-scale special hydraulic presses, sun visor laminating machines, automatic feeding machines and other equipment of various specifications and models, providing equipment and process guarantee for products; it has a mold processing center, which can independently design and process molds, reducing mold costs and development cycles; it has an advanced laboratory with dozens of experimental equipment, which can carry out product and material experiments and has passed customer laboratory audits and approvals, providing effective testing methods for product quality.

Production and R&D

It has an advanced laboratory with dozens of experimental equipment, which can carry out product and material experiments and has passed customer laboratory audits and approvals, providing effective testing methods for product quality.

The company supplies parts to domestic and foreign auto manufacturers such as FAW Group, Changan Group, JAC Group, BAIC Group, and BAIC Foton, and also supplies parts to engineering machinery companies such as Doosan Engineering Machinery, Clark, Trelleborg, Nacco, Spanish Ossa, Heli, and Anhui Jianghuai Heavy Industry. The products have fully realized independent research and development, design, and manufacturing.

Relying on industry technology, excellent product quality, lean production processes and innovative development strategies, the company has established its position in the Chinese market and expanded into overseas markets. It is courageous in innovation, constantly breaking through and shaping a new image for Chinese auto parts enterprises and building a new type of enterprise with high quality, high technology and high efficiency!

Service Process

Original manufacturer, price controllable

Product customization is supported, and parts with complex shapes can be manufactured

Diversity of material selection

Use better raw materials and processes

Better technology and equipment

A complete after-sales service team

Blog & News

If you want to learn more about Hengtai, please visit the news section of our website

Company's 2022 hazardous waste pollution prevention and control information

Company's 2022 hazardous waste pollution prevention and control information

Focus: Water resource management system to be released this year

Huang He, deputy director of the Development Research Center of the Ministry of Water Resources, recently revealed to the China Securities Journal reporter that, in order to implement the "water resources management system" proposed at the Central Water Conservancy Work Conference, the Ministry of Water Resources is studying and formulating a series of specific implementation plans, which will be announced this year.

Following the release of emission standards for industries such as rare earth and batteries, the Ministry of Environmental Protection recently released the "Technical Specifications for Wastewater Treatment in the Monosodium Glutamate Industry" (Draft for Comments), requiring enterprises to adopt standardized technologies and processes for wastewater treatment. According to the Ministry of Environmental Protection, in addition to the "Technical Specifications", the ministry is revising the national emission standard for pollutants in the monosodium glutamate industry issued in 2003, setting even higher requirements for specific emission limits, such as organic wastewater and chemical oxygen demand (COD). According to the Ministry of Environmental Protection's plan, over the next 5 years, the ministry will successively formulate or revise emission standards for a series of fields, including industrial wastewater from steel and pharmaceutical industries, and oily wastewater from offshore oil development. Industry analysts point out that the continued environmental protection storm may trigger a wave of industrial integration in many sectors, and enterprises and products with innovations in environmental protection technologies and processes will generally benefit. 100 standards to be rolled out Since the beginning of this year, emission standards for industries such as rare earth, lead-acid batteries, and thermal power have been successively put on the agenda, and their impact on various industries is gradually becoming apparent. After the environmental protection storm hit the lead-acid battery industry, it is generally believed that nearly 90% of enterprises face elimination. According to the reporter's understanding, within the next 5 years, the Ministry of Environmental Protection will introduce 100 national standards covering water pollutants, air pollutants, solid waste and chemical pollutants, and noise pollution for various industries. In terms of industrial wastewater pollution control, future key industries will involve steel, pharmaceuticals, and offshore oil engineering. Some analysts also believe that while the introduction of environmental protection standards will theoretically have a certain impact on related industries due to the high requirements for pollutant emission indicators, the implementation and enforcement of the standards will determine the extent of the industry's impact. Therefore, the potential impact on various industry markets will depend on the subsequent implementation policies.

According to the Ministry of Environmental Protection's plan, in the next five years, the Ministry will gradually formulate or revise emission standards for a series of fields, including industrial wastewater from steel and pharmaceutical industries, and oily wastewater from offshore oil development. Industry analysis points out that the continuous environmental protection storm may trigger a wave of industrial integration in many fields, and enterprises and products with innovations in environmental protection technologies and processes will generally benefit from it.

Email:

Telephone:

Message Form